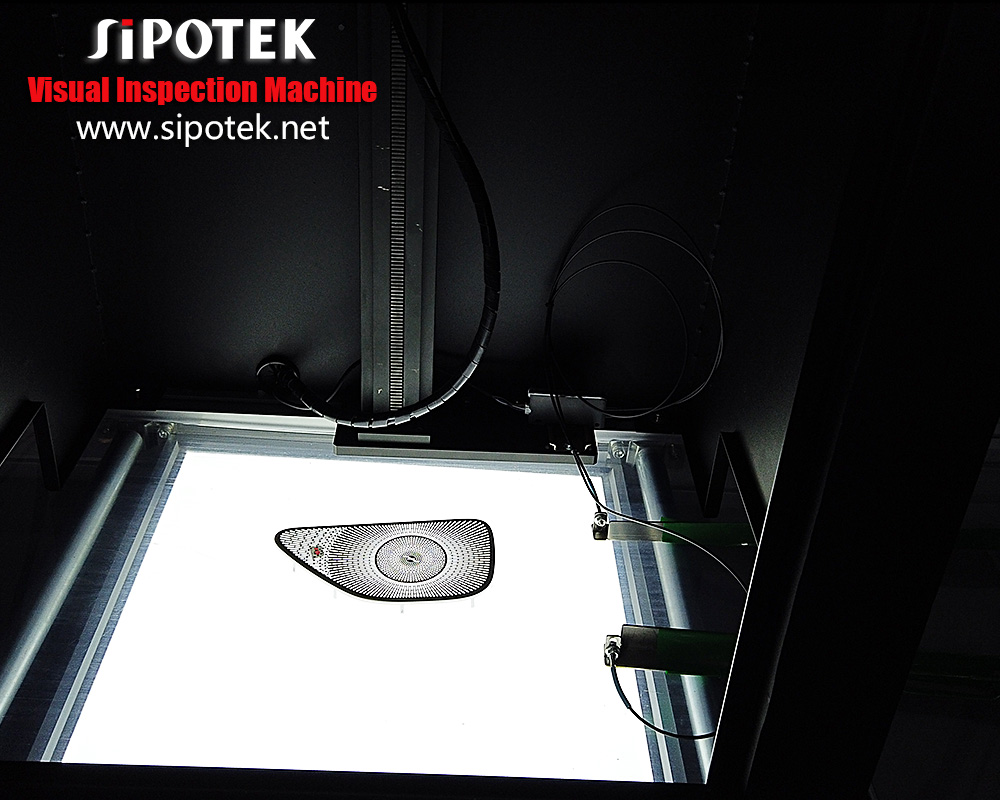

With the development of the automation industry, the application of machine vision technology has been extensive growing. For example, in the automated manufacturing industry, machine vision measure and inspect various dimensional parameters of the accessory parts, such as length measurement, circle measurement, angle measurement, arc measurement, area measurement, etc.. It can not only obtain the size parameters of the online product, but also commonly applied in products that are made online for real-time determination and sorting.

The inspection system that based on machine vision technology has the advantages of low cost, high precision and easy installation. Coupled with powerful visual software, easy to adjust, flexible and convenient, and measurement data can be stored, easy to establish statistical analysis, easy to quickly find problems, solve problems, the inspection system is the best choice for industry testing technology.

However, in some machine vision inspection projects, many customers have encountered the problem of detection accuracy. For example, the detection of some machine parts for the outer dimensions, inner and outer diameters, is required to reach accuracy of 10um. At present, many cameras with a configuration of 5 million are theoretically capable of achieving an accuracy of 10 um. However, the accuracy from the actual test is far less than the 10um, and it is very good to be able to achieve 30um. The main reasons for the large errors scope are as follows:

- The industrial cameras

Many customers choose CMOS cameras for cost considerations. When shooting the edges of objects, the contrast of edge contours is poorer, and the noise is larger, which brings large errors for software measurement. It is usually recommended to use CCD cameras.

Coupon Code: free shipping coupon code: freeshipping on any order from sipotek.net

2, The camera lens

Many mechanical parts have height difference and a large depth of field (DOF). However, due to the viewing angle factor, the ordinary lens is difficult to capture the inner wall of the component, which makes it difficult to find the most realistic and accurate edge contour during software processing, and puts higher requirements on the image processing algorithm.

3, The light source

Many customers will choose an ordinary backlight. When the visual inspection accuracy is not high, the backlight has a price advantage. Under the premise of high requirements, the principle of the backlight is to use light to produce uniform and soft light through the diffuse reflector, and the light generated at a certain point will diverge at any angle to the space. When detecting a circular or cylindrical object, diffraction occurs at the edge of the object to be measured. At the same time, the brightness of the light source also has a great influence on the brightness and darkness in the image.

Visit https://www.sipotek.net/ for more information about CCD camera inspection machine application.

Since its establishment 16 years ago, Shenzhen Sipotek Technology Co., Ltd has been committed to the research, development and manufacturing of image technology and machine vision, with more than 70 senior R&D personnel of machine vision system and industrial automation engineers. The company’s key technical personnel are mainly from HUAWEI, BYD, FOXCONN and other first-class manufacturing enterprises, with many years of mature experience in software design, visual and image comparison technology, industrial automation and other aspects.

For Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86 18666216027

Email: info@sipotek.net

Website: https://www.sipotek.net